Establishing a visual inspection training program is a critical activity of any cleaning program strategy which leverages visual inspection as a sampling method.

With the ultimate goal of empowering our clients to confidently and independently conduct future trainees, Hyde subject matter experts are available to travel on-site to conduct visual inspection qualification using methods that enable qualitative and quantitative evaluation of operators.

Hyde delivers the qualification of trainees and future trainers, a test plan and training materials, and a final summary report.

The development of a visual inspection program is a key component of the cleaning validation monitoring strategy. It is predicated on an understanding of the visual detection capability associated with the equipment design and the process soils themselves.

The execution of VRA studies provides the qualitative and quantitative information necessary to understand if the process soils can be consistently detected under viewing conditions meant to simulate site constraints.

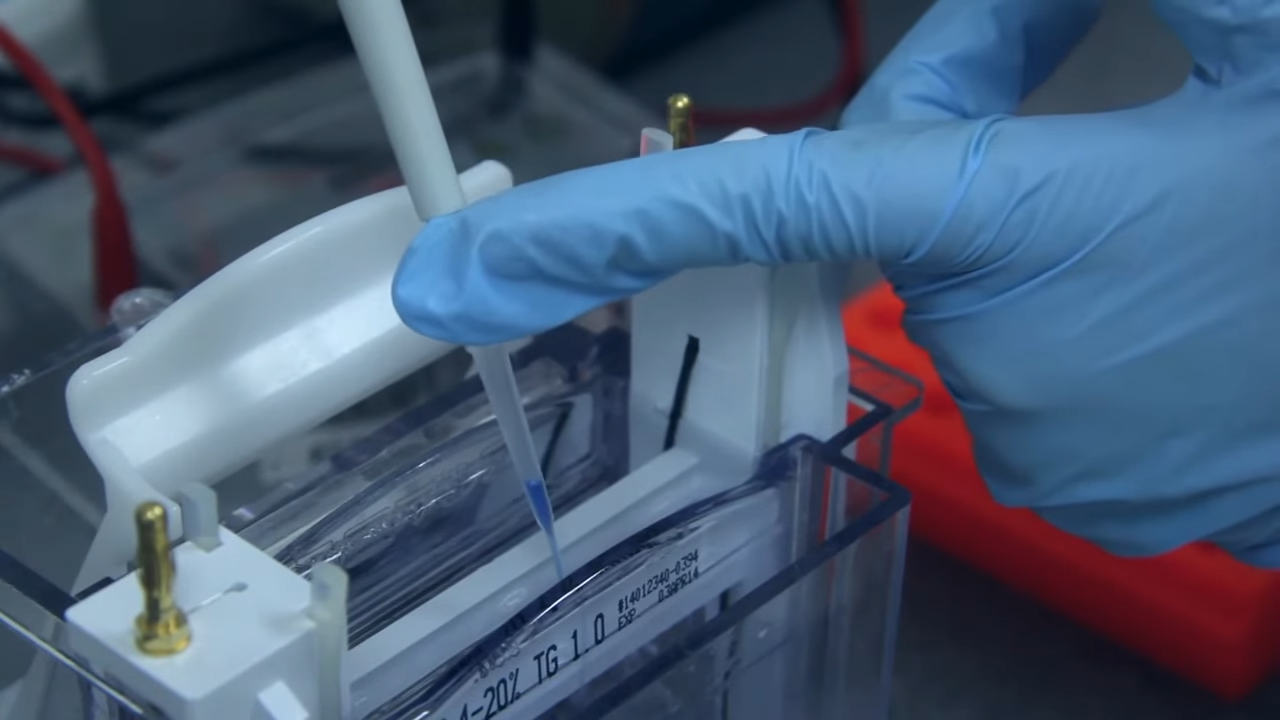

Hyde will help establish the foundation for a successful swab sampling qualification program by traveling on-site to qualify a group of operators and future trainer(s) to conduct swab sample collection.

Training includes a qualification protocol, classroom instruction, hands-on swab qualification, analysis of samples using the current detection method, summary report, presentation materials, and certificates of qualification.

With an identified worst-case residue and cleaning agent selected, design space exploration uses a Design of Experiments (DOE) approach to the interdependency of temperature and chemical concentration.

Design space exploration allows for a selection of optimal cleaning parameters that can be scaled up to pilot and production processes to reduce cleaning times, cleaning agent concentrations or temperatures, and cost.

The determination of acceptable carryover or residue limits for product soils, excipients, or cleaning agents into subsequent product batches. Acceptance limits are established to ensure the safety, quality, and efficacy of batches as a critical component of any cleaning program.

Cleaning method development is performed in alignment with ICH Q2(R1) guidelines for the validation of analytical procedures. Once developed, Hyde will employ the method for analysis of swab and rinse recovery samples or validate at the client or third-party laboratory testing site.

The Hyde Analytical Laboratory develops assays required to assess equipment cleanliness and confirm the removal of product soils and cleaning by-products using various analytical methods.

Additionally, drug product release methods may be developed and transferred to the desired third-party laboratory for routine testing.

Utilizing an existing cycle or cycle identified during cleaning optimization studies, multiple residues are evaluated to establish a worst-case ranking matrix from a cleanability perspective. Identification of a worst-case residue can be leveraged to reduce full-scale cleaning validation activities and decrease costs.

Hyde authors high-level strategic and procedural cleaning program documentation, including risk assessments to identify gaps in agency requirements related to cleaning validation.

Comprehensive routine cleaning sample testing to address a variety of process impurities. This includes Total Organic Carbon (TOC) analysis, Conductivity testing, High and Ultra-high Performance Liquid Chromatography (HPLC) for precise detection and identification of residues, Endotoxin testing, and Ultraviolet-Visible (UV-Vis) Spectroscopy. Each of these tests plays a crucial role in maintaining stringent quality control and ensuring that cleaning procedures meet specifications.

Microbial reduction studies can be used to generate evidence that cleaning procedures or conditions effectively remove microbial contamination from surfaces. Coupon or direct spike methods may be used in combination with a rapid microbial method (RMM) and/or endotoxin analysis for the detection of microbial residues.

Determination of the most effective cleaning agent and assessment of the most suitable cleaning conditions for the particular residue. Cleaning agent screening studies may be used as a first step in the harmonization of cleaning cycles to increase operational efficiency or the development of unique cleaning chemistries for individual equipment operations to reduce cost and water usage.

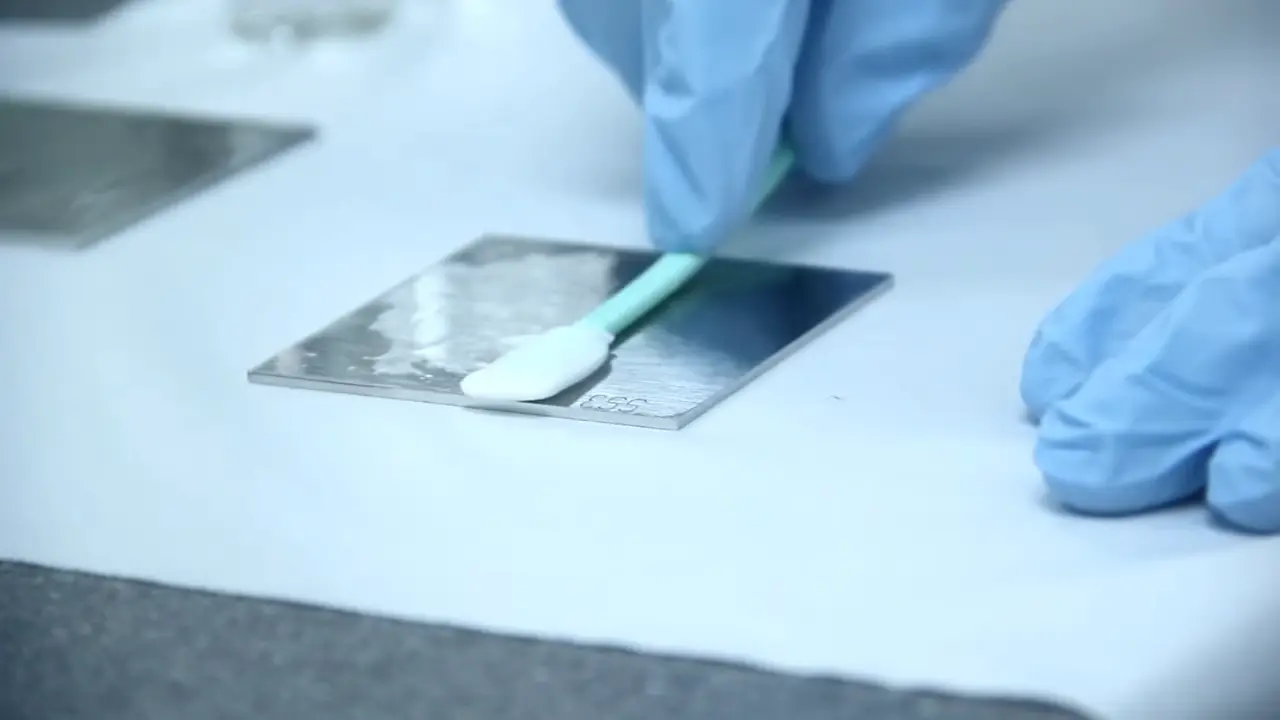

Recovery studies are required to demonstrate that the analyte of concern can be recovered from equipment surfaces using the selected sampling method of swabbing or rinsing. Hyde performs formal swab and rinse studies to demonstrate accurate and repeatable recovery and establish recovery factors as needed.

Every analytical technique has its performance limitations and limitations for specific analytes. Robust analytical method development, therefore, requires an understanding of both the analyte and the requirements for method performance before selecting an analytical technique or developing method parameters.

Hyde’s experience in analytical method selection and development for cleaning can help clients select appropriate techniques based on the analyte and the carryover limits to ensure robust analytical cleaning methods fit for their intended use.

Michael Lund

Senior Scientist, Hyde Analytical Laboratory

View LinkedIn Profile

Lab-scale cleaning studies take the guesswork out of full-scale cycle development and reduce the surprises that may come up during cleaning validation. The world of cleaning often throws curveballs that go against what one would assume to be true.

Our lab studies have often provided empirical results that demonstrate the opposite of the theoretically assumed behavior. By identifying and characterizing these behaviors at small scale, we set our clients up for faster, cheaper, and more successful full-scale cleaning cycle development and cleaning validation.

One small-scale cleaning study can provide such a range of benefits to our clients – from something as straightforward as providing empirically derived starting points for full-scale cycle development to something more unexpected like identifying the need to validate cleaning cycles immediately after draining a tank because the process soil being used for validation actually becomes easier to clean as it dries, which would not appropriately challenge the cleaning validation activities.

Michelle Monk

Head of Projects, Hyde Analytical Laboratory

View LinkedIn Profile

Cleaning validation samples are not testing for the quality or release of the water used during production and therefore it is not appropriate to use a compendial method that was designed for water testing.

Cleaning validation sampling is not testing water for water purity but rather for the presence of residual soils remaining after cleaning activities. The FDA expects that testing is performed for contaminants and not water quality.

Nicole Collier

Principal Engineer, Hyde Analytical Laboratory

View LinkedIn Profile